Our Services

ABOUT BARKENS HARD CHROME (BHC)

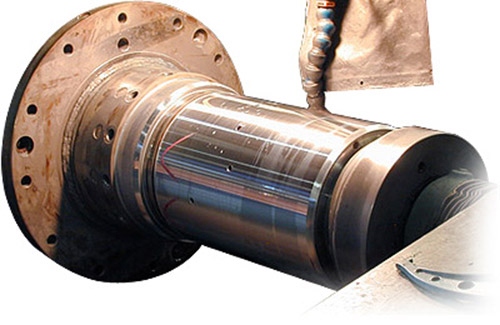

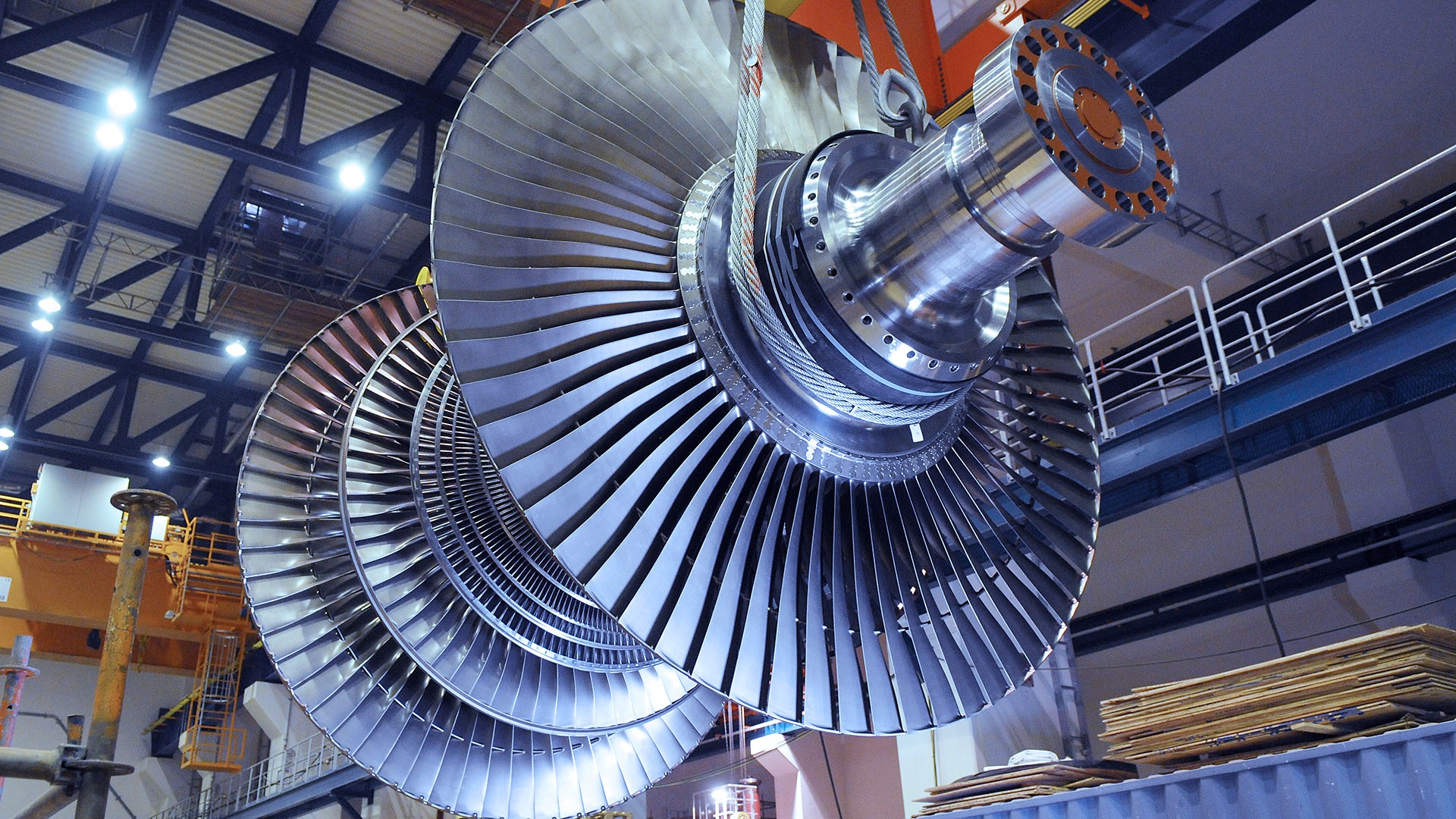

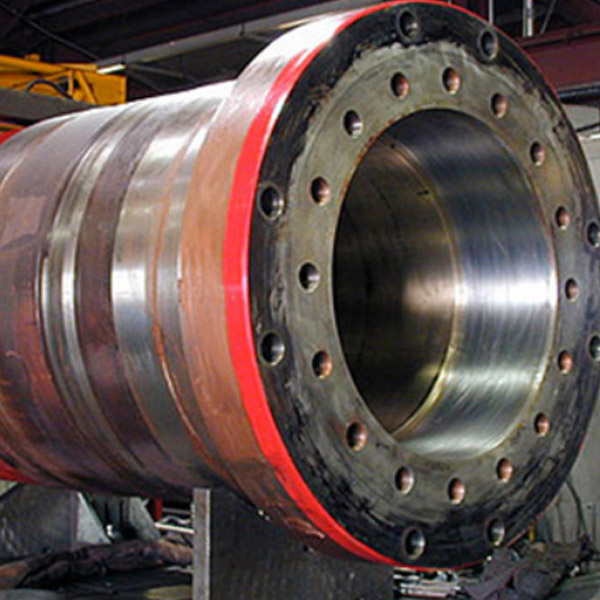

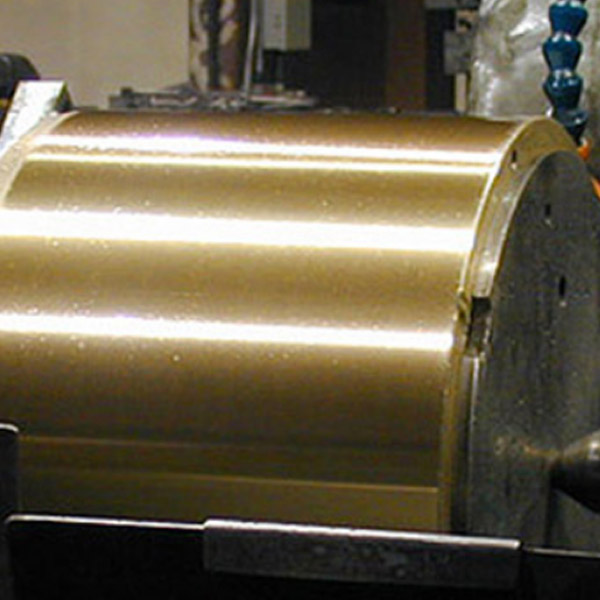

BARKENS HARD CHROME (BHC) is an AS9100/ISO9001 and Nadcap accreditedMetal Finishing Company, providing the most recent metal finishing technologies for the prevention of wear, corrosion, galling and friction, beyond aesthetic appeal. BHC specialize in Hard Chrome Engineered Plating and Precise Grinding, serving an immense range of application, for a vast range of industries includingAerospace, Military, Défense, Space, Marine and commercial sectors that includePetroleum/Gas and Turbine companies. Our founder was among the pioneers of hard Chrome plating, who infused his intellectual knowledge and expertise to the company, that’s carried out to this day.Our Chrome Process Tanks can accommodate cylindrical parts up to 40-feet in length, 72 inches in Diameter, weighting up to 15-tons or parts thatfit in a 5W x 12L x 9H feet tank. Smaller chrome plating tanks are also available for intricate parts.

We work with a wide range of metals including high-performance/high strength aerospace alloys.

We also offer Electroless Nickel and Cadmium Plating, PhosphateCoating, Stripping, Cleaning, Passivation of metals and Temper/Nital Etch Inspection, meeting Federal, Industrystandards and equivalentcustomer specifications.

Our grinding capabilities include Blanchard and Cylindrical Grinding, capable of holding tolerances up to ± 0.0005 inch and surface finish up to16-Ra or better.

Want to Know More About our Hard Chrome Plating Services?

Hard chrome plating customers expect quality and service for their exacting projects, and BHC Industries has always prided itself in meeting that challenge.

We are able to process in accordance with most military, federal and proprietary hard chrome plating specifications.