-

NADCAP

-

AS9100/ISO9001

-

API Q1 – American Petroleum Inc

-

US AIRFORCE

-

US/European Prime Contractors& Tier Suppliers( Accepting Nadcap Approval/ Industry Specs)

-

FAA Repair Stations

-

Marvin Engineering Co.

-

Solar Turbines

-

SpaceX

-

Baker Hughes

-

National Oil Well/VARCO

| Plating Material |

Hard Chrome Manganese Phosphate |

| Finishes | Bright Satin |

| Substrate |

Steel (300M to high tough material) Metal Sprays |

| Processes | Passivating Phosphating |

| Equipment |

Plating Tanks 3: 10' L x 60" w x 108" D |

|

Maximum Part Length |

52 ft 624 in |

|

Maximum Part Height |

32 ft 384 in |

|

Maximum Part Diameter |

6 ft 72 in |

|

Maximum Weight |

20 tons 40,000 lb |

|

Plating Thickness |

.0005 to .010 in |

|

DC Rectifiers |

80,000 amperes |

|

Preplate Operations |

Aluminum Oxide (Sand) Blasting Shot Peening |

|

Chrome Plating Bath Solution |

High Efficiency Etch Free (HEEF) |

|

Postplate Operations |

Polishing Grinding |

|

Additional Services |

Grinding Shot Peening |

| Industry Focus |

Energy Aerospace |

|

Intended Application |

Pump Barrels Off-Shore Equipment |

|

Industry Specifications |

Aerospace Material Specification (AMS) Boeing (BAC) |

| Efficiency |

Lean Manufacturing |

|

File Formats |

AutoCAD |

-

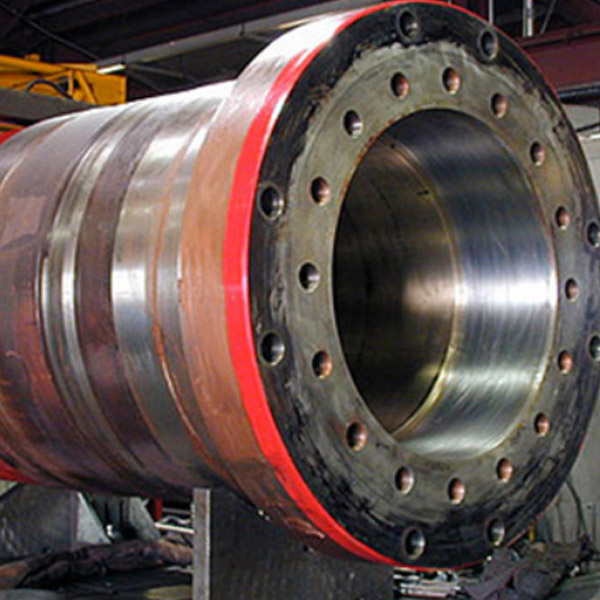

Drilling Rig Rotor Shaft Plating

At BHC Industries Plating, we've been servicing customers in the petroleum industry since 1942. Working with heavy industry requires us to possess capabilities to accommodate the large scale requirements of this industry. The 55' drilling rig rotor shaft highlighted here exemplifies these capabilities.

This project posed not only machining and plating challenges but also several logistical challenges as Learn More

-

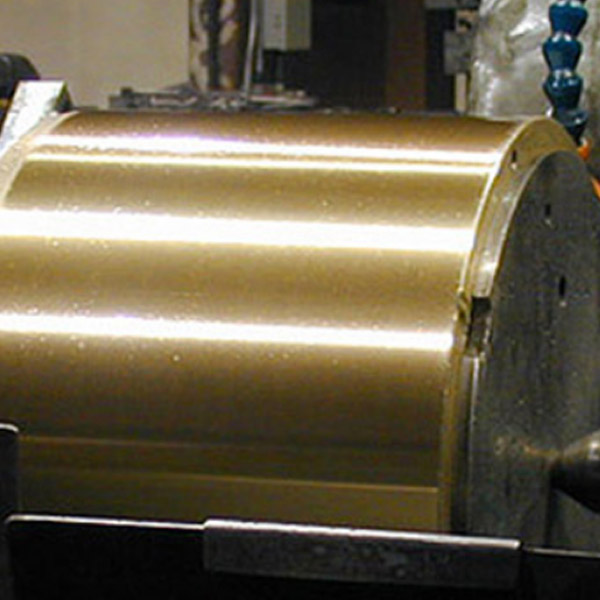

Natural Gas Turbine Plating & Grinding

A customer in the solar power industry contracted us to repair a number of natural gas turbines with hard ID grinding (inside diameter) and chrome plating. The turbines, which were manufactured from a proprietary forging, had dimensions that ranged in size up to 22" in diameter.

ID grinding was completed on our advanced Heald 273A ID grinder, this capability allows us to grind inside diameters up to 24", and features a 24" swing. Once the ID surface was prepared we appl Learn More

-

Artificial Lift Pump Barrel Plating

Artificial lifts are a mainstay of the US petroleum industry; in fact 96% of US wells require some form of artificial stimulation for crude extraction. Pump barrels are a crucial component of artificial lifts and a heavy wear item, operating an oil extraction operation requires constant refurbishment of pump barrels. Because of the sheer volume of refurbishments and the precision required, a cost effective solution is a must.

Low cost Asian solutions are problematic; the precision req Learn More

-

Drilling Rig Main Shaft Coating

The project highlighted here exemplifies our ability to apply precision grinding and coating processes to large diameter shafts. This customer needed a phosphate coating applied to shafts with variable outside diameters of 8" to 24". Prior to coating the shafts are sand blasted, and then ground on our Landis OD Grinder, which features a 30" swing, and is capable of grinding components up to 240" between centers, and up to 12,000 lbs.

Once the shaft surface is prepa Learn More

-

Aerospace & Oil Industry Electroless Plating

To better accommodate the diverse needs of our customers we also offer electroless nickel plating. Electroless plating has long been known for characteristics such as uniform application, its lubriciousness, solderability, and high resistant to corrosion. In most application these features would be enough, however at BHC Industries Plating; we're continually looking for ways to improve our processes. That's why we use AutoTech Heath 25 hard chrome plating in Learn More